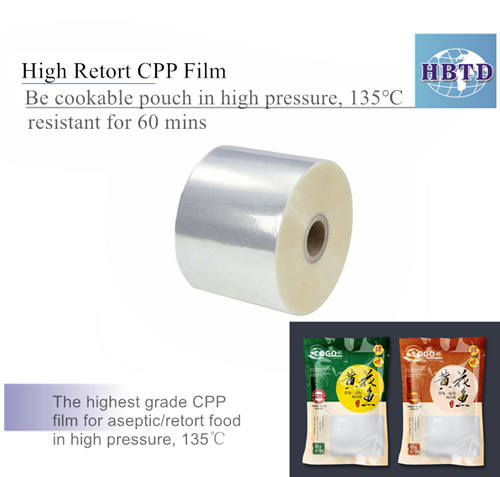

Retort CPP

135 degree resistant RCPP film - 副本

- Width : 150mm - 2400mm

- Thickness: 50 - 90 microns

- Material: PP(polypropylene) by casting

- Layers: 3 layer co extruded

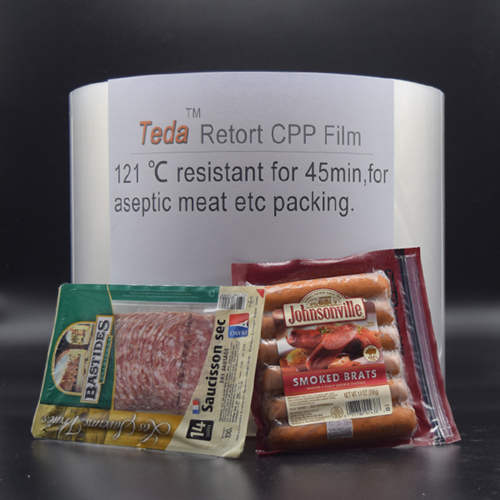

- Product description: 135℃ resistant for 45 min, semi retort cpp film, for aseptic product, like sausage, meat ... -10℃ resistant.

Description:

The highest retort CPP film, this 135 degree resistant RCPP film is designed to has 135 ℃ resistant for 60 min, not commonly 120 ℃ resistance. With high retort 60 min, the asepticizing for food would get most effect. It is an co-extruded polypropylene film, one side be designed for aseptic/ retort packaging as the sealing layer, the other side treated with Corona to be laminat with other material. It is very ideal material to pack sausage, meat products, and other high temperature asepticizing.

To laminate with other material for flexible packaging. Please tell the lamination purpose, the dry lamination, non-solvent lamination or PP extrusion lamination to get right option.

Key Feature:

-135 ℃ resistant for 60 min.

-cold resistance by -10 ℃.

-Excellent hermetic seal.

-High retort with full aseptic application.

APPLICATION:

For food packaging, met retort product, aseptic causage meat product ...

|

PROPERTIES |

TEST METHOD |

UNIT |

TYPICAL VALUE |

|||

|

THICKNESS |

D-2673 |

Microns |

RCPP Plain 60 70 |

TZ1RCPP anti puncture 60 70 |

TZ3RCPP very anti-puncture 60 70 |

|

|

FILM DENSITY Corona Level/Wetting tensile COEFF OF FRICTION (Dynamic) (Static) HAZE JOINTS NUMBER SECTION FLETNESS |

D-792 D-2578 D-1894 D-1894 D-1003 International International |

gm/cc Dyne/cm - - - m2 - |

0.91 0.91 38 38 0.168 0.148 0.172 0.156 3.97 4.05 ≤1 ≤2 mm |

0.91 0.91 38 38 0.133 0.124 0.136 0.125 4.65 4.44 ≤ 1 ≤ 2 mm |

0.91 0.91 38 38 0.136 0.132 0.147 0.135 4.47 4.95 ≤ 1 ≤ 2 mm |

|

|

TENSILE STRENGTH AT BREAK |

MD* TD* |

D-882 |

MPa |

46.7 44.6 32.5 31.8 |

43.2 42.2 32.0 31.4 |

43.0 42.1 32.1 30.2 |

|

ELONGATION AT BREAK |

MD* TD* |

D-882 |

% |

636.7 642.1 738.4 722.5 |

765.4 745.3 872.3 865.7 |

743.2 743.6 865.4 846.9 |

|

HEAT SEAL TEMPERATURE |

1s, 300KPa, 60℃ for under lay |

℃ |

151 153 |

151 153 |

151 153 |

|

|

HEAT SEALING STRENGTH |

D-882 |

N/15mm |

≥18.9 ≥20.0 |

≥16.3 ≥18.3 |

≥15.5 ≥17.0 |

|

|

DROP IMPACT |

- |

- |

440g 560g |

800g 920g |

1040g 1100g |

|

| FINISH | No Folding, Air bubble fracture, Perforation, Scratches, Impurities, Oil. | |||||

|

EXPLAINATION |

*MD = MACHINE DIRECTION *TD = TRANSVERSE DIRECTION *Tensile Unit 'N/15mm' is China standard, in other areas, also use unit 'N/25mm', the testing date should be different. |

|||||

Categories

Latest News

Contact Us

Contact: Oskar

Phone: +86 173 322 68603

Tel: +86 173 322 68603

Add: xiongxian, baoding city, hebei province, China.