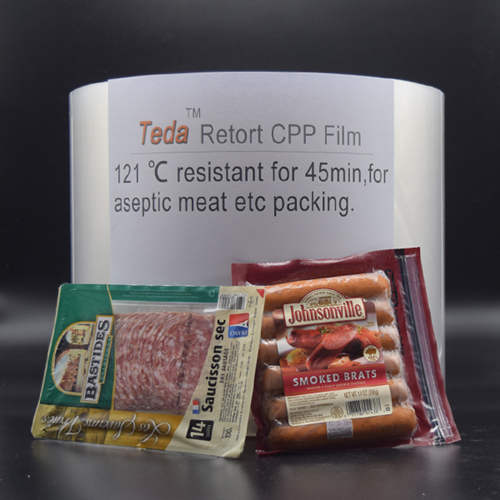

Retort CPP

Plain RCPP film

- Width : 150mm - 2400mm

- Thickness: 50 - 90 microns

- Material: PP(polypropylene) by casting

- Layers: 3 layer co extruded

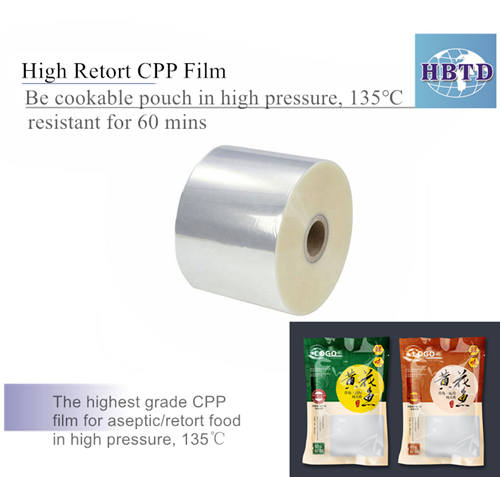

- Product description: 121℃ resistant for 45 min, semi retort cpp film, for aseptic product, like sausage, meat ... -10℃ resistant.

Description:

The Plain RCPP Film is an co-extruded polypropylene film, one side be designed for aseptic/ retort packaging as the sealing layer, the other side treated with Corona to be laminat with other material. This retort CPP film has a property resistant 121 ℃ for 45 min and -10 ℃ resistance. It is very ideal material to pack sausage, meat products, and other high temperature asepticizing.

To laminate with other material for flexible packaging. Please tell the lamination purpose, the dry lamination, non-solvent lamination or PP extrusion lamination to get right option.

Key Feature:

-121 ℃ resistant for 45 min.

-cold resistance by -10 ℃.

-Excellent hermetic seal.

-Economic RCPP film.

APPLICATION:

For food packaging, met retort product, aseptic causage meat product ...

|

PROPERTIES |

TEST METHOD |

UNIT |

TYPICAL VALUE |

|||

|

THICKNESS |

D-2673 |

Microns |

RCPP Plain 60 70 |

TZ1RCPP anti puncture 60 70 |

TZ3RCPP very anti-puncture 60 70 |

|

|

FILM DENSITY Corona Level/Wetting tensile COEFF OF FRICTION (Dynamic) (Static) HAZE JOINTS NUMBER SECTION FLETNESS |

D-792 D-2578 D-1894 D-1894 D-1003 International International |

gm/cc Dyne/cm - - - m2 - |

0.91 0.91 38 38 0.168 0.148 0.172 0.156 3.97 4.05 ≤1 ≤2 mm |

0.91 0.91 38 38 0.133 0.124 0.136 0.125 4.65 4.44 ≤ 1 ≤ 2 mm |

0.91 0.91 38 38 0.136 0.132 0.147 0.135 4.47 4.95 ≤ 1 ≤ 2 mm |

|

|

TENSILE STRENGTH AT BREAK |

MD* TD* |

D-882 |

MPa |

46.7 44.6 32.5 31.8 |

43.2 42.2 32.0 31.4 |

43.0 42.1 32.1 30.2 |

|

ELONGATION AT BREAK |

MD* TD* |

D-882 |

% |

636.7 642.1 738.4 722.5 |

765.4 745.3 872.3 865.7 |

743.2 743.6 865.4 846.9 |

|

HEAT SEAL TEMPERATURE |

1s, 300KPa, 60℃ for under lay |

℃ |

151 153 |

151 153 |

151 153 |

|

|

HEAT SEALING STRENGTH |

D-882 |

N/15mm |

≥18.9 ≥20.0 |

≥16.3 ≥18.3 |

≥15.5 ≥17.0 |

|

|

DROP IMPACT |

- |

- |

440g 560g |

800g 920g |

1040g 1100g |

|

| FINISH | No Folding, Air bubble fracture, Perforation, Scratches, Impurities, Oil. | |||||

|

EXPLAINATION |

*MD = MACHINE DIRECTION *TD = TRANSVERSE DIRECTION *Tensile Unit 'N/15mm' is China standard, in other areas, also use unit 'N/25mm', the testing date should be different. |

|||||

Categories

Latest News

Contact Us

Contact: Oskar

Phone: +86 173 322 68603

Tel: +86 173 322 68603

Add: xiongxian, baoding city, hebei province, China.